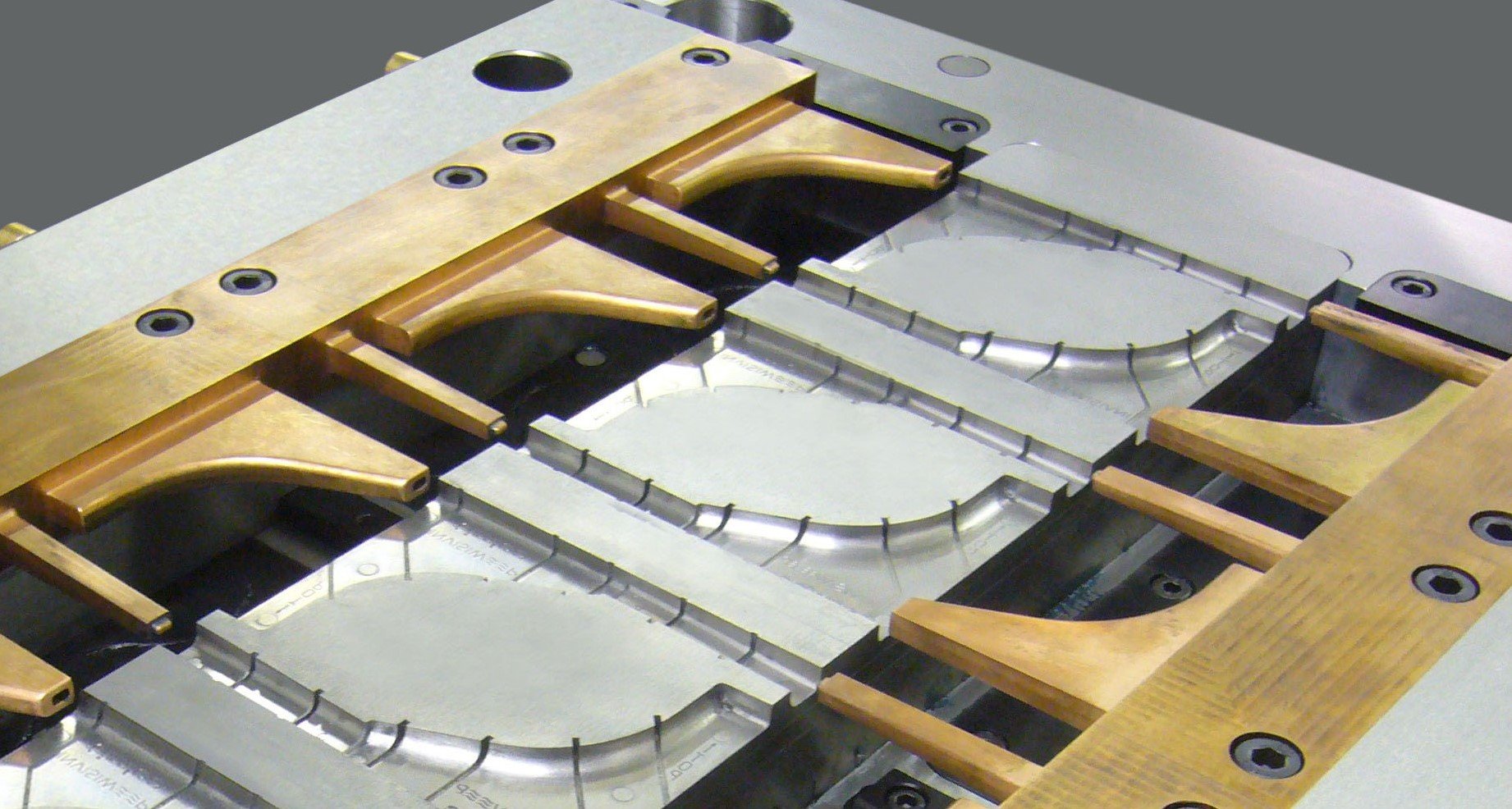

PLASTIC INJECTION MOULD TOOLMAKING

Faulkner Moulds, three times UK Toolmaker of the Year winner, has almost 30 years’ experience of award-winning plastic injection mould toolmaking and product and tool Design for Manufacture.

Continually investing in pioneering toolmaking technology and skills, Faulkner Moulds UK toolmakers produces long lasting, high production and low maintenance plastic mould tools.

Through our dedicated design consultation service, we create a smooth and efficient manufacturing process, producing plastic injection moulds of superb quality.

As Design for Manufacture specialists, we fully consider how tooling will be used in practice, incorporating this into each design. Therefore, we regularly reduce costs for our customers in the short, medium and longer term.

We offer a full 1 or 2 million shot tooling guarantee on our mould tooling and serve many sectors including medical, electronics, packaging, consumer, industrial and automotive.

For detail on our MACHINING CAPACITY, scroll further down. Our range of services includes:

- Superb quality award-winning plastic injection mould toolmaking

- Multi-cavity high production tooling with quick cycle time

- Design for Manufacture principles

- Complex tooling solutions

- Mould tools for medical, electronics and packaging

- Twin shot tools / two shot tools / 2K tools

- 5-axis machining

- Innovative wire erosion strategies

- Component design full consultation service

- Helping inventors develop ideas into a design ready for production

- 3D printing / Stress Analysis

- Reverse engineering

- Fully hardened tools

- Graphite machining / electrode machining

- Stripper plates

- Side movers

- Unscrewing cores

- Up and aways

- Hot runner, conventional or 3-plate feed

- Single impression and multi-cavity tools

- Overmould tools

- 3 tons capacity

- CNC machining

- CNC sparking