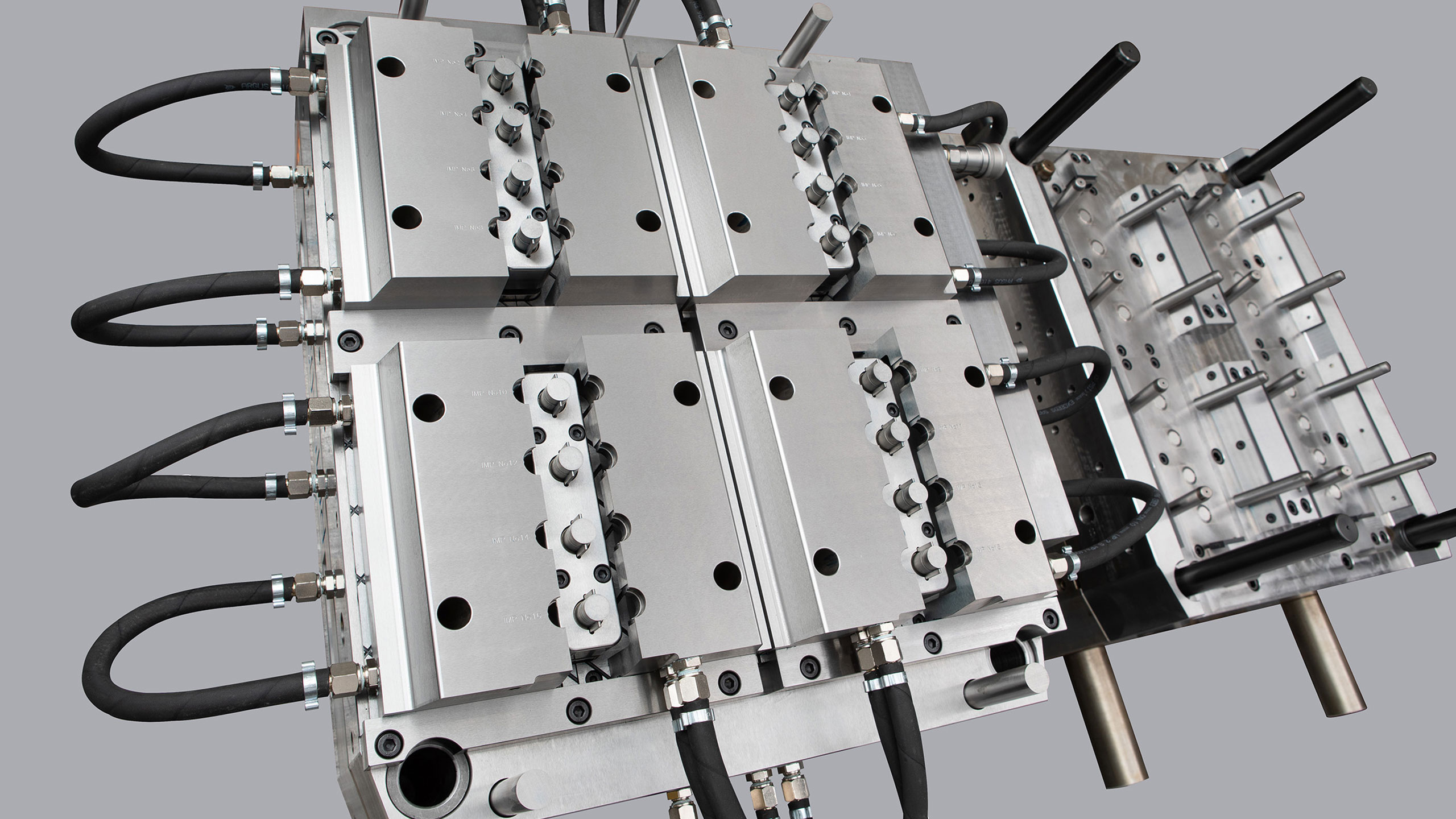

MULTI-CAVITY HIGH PRODUCTION TOOLS

Faulkner Moulds has sound experience in high production multi-cavity mould tooling for many sectors including medical and packaging.

The tool pictured has 16 impressions, is guaranteed for a million shots and moulds at an efficient 7 second cycle time. Faulkner Moulds recently reduced the cycle time on a new 12 impression caps and closures packaging tool for a household name, from a target of 8.5 seconds to just 6.98 seconds.

In 2022, we again installed trail-blazing technology at our Yorkshire-based toolroom – a production cell which particularly supports multi-cavity, high-production tooling.

The production cell has created significant efficiencies which we have been pleased to pass on to our customers. The new, innovative robotic system is, we believe, a ‘world-first’, further enhancing the quality and efficiency of our mould tool manufacture.