EXPERIENCE | GALLERY

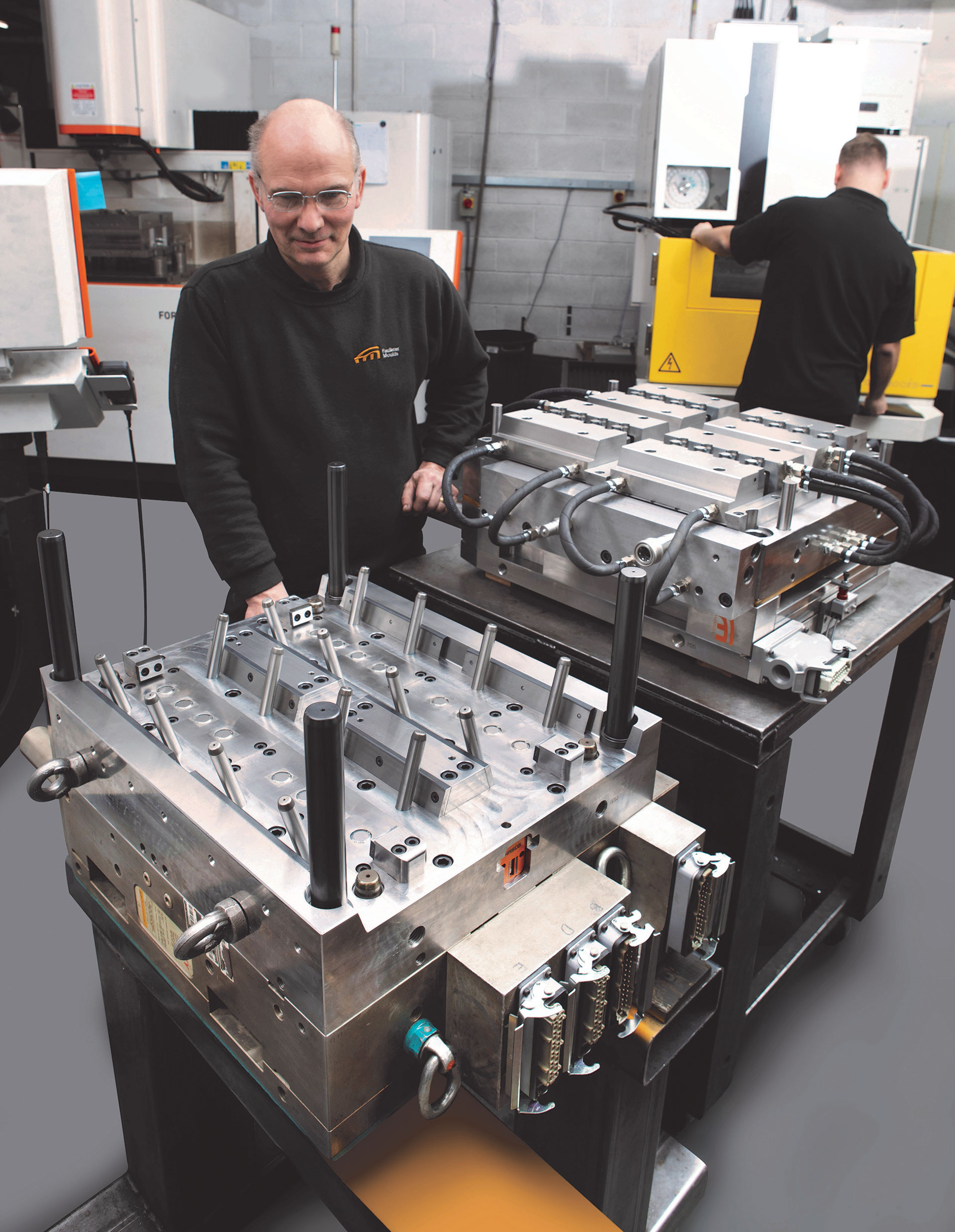

Faulkner Moulds has over 30 years of toolmaking excellence, and in 2019, 2018 and 2016 we won the prestigious UK Plastics Industry Award for ‘Supplier Partnership: Toolmaker’ (known as the UK ‘Toolmaker of the Year’ award).

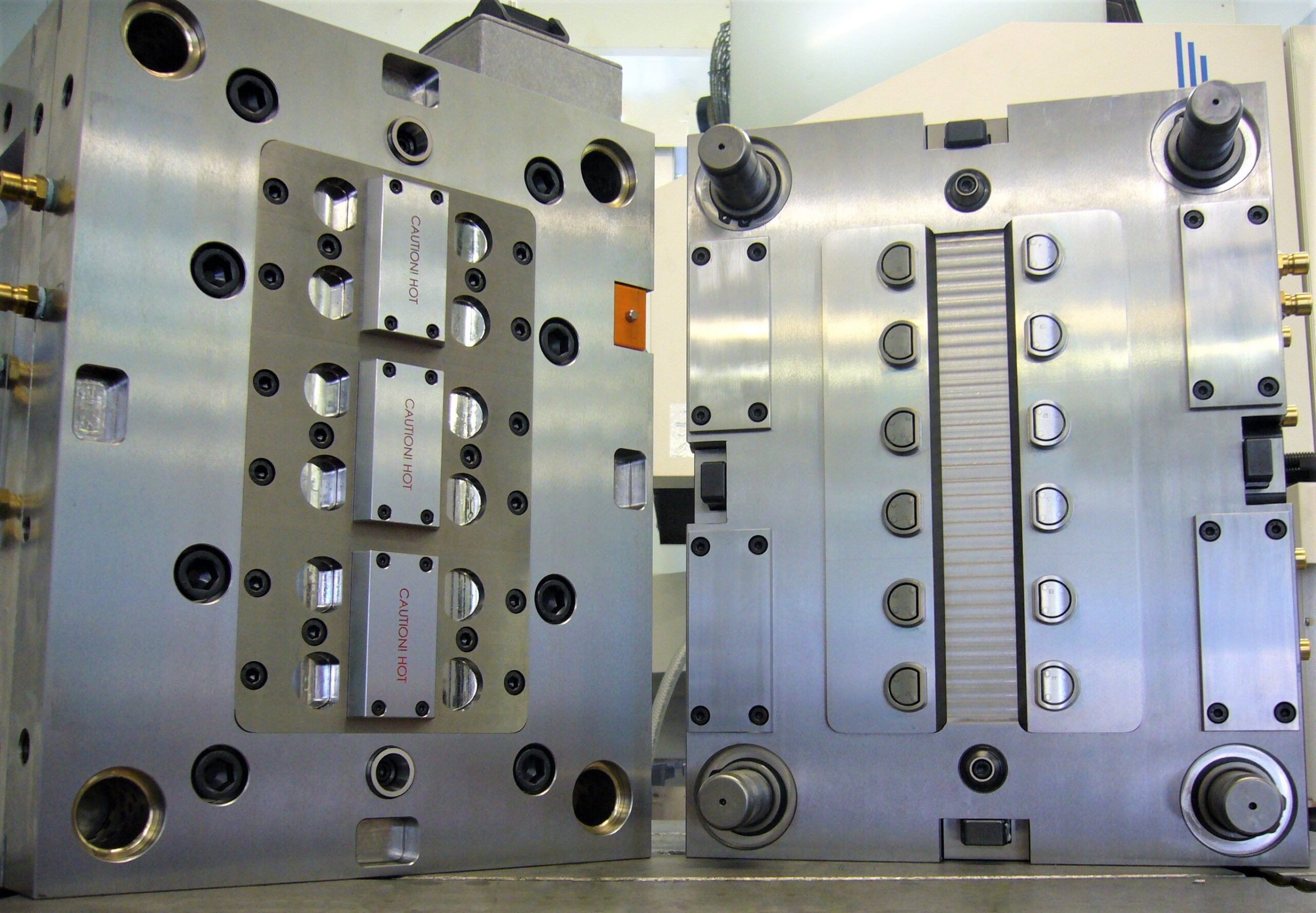

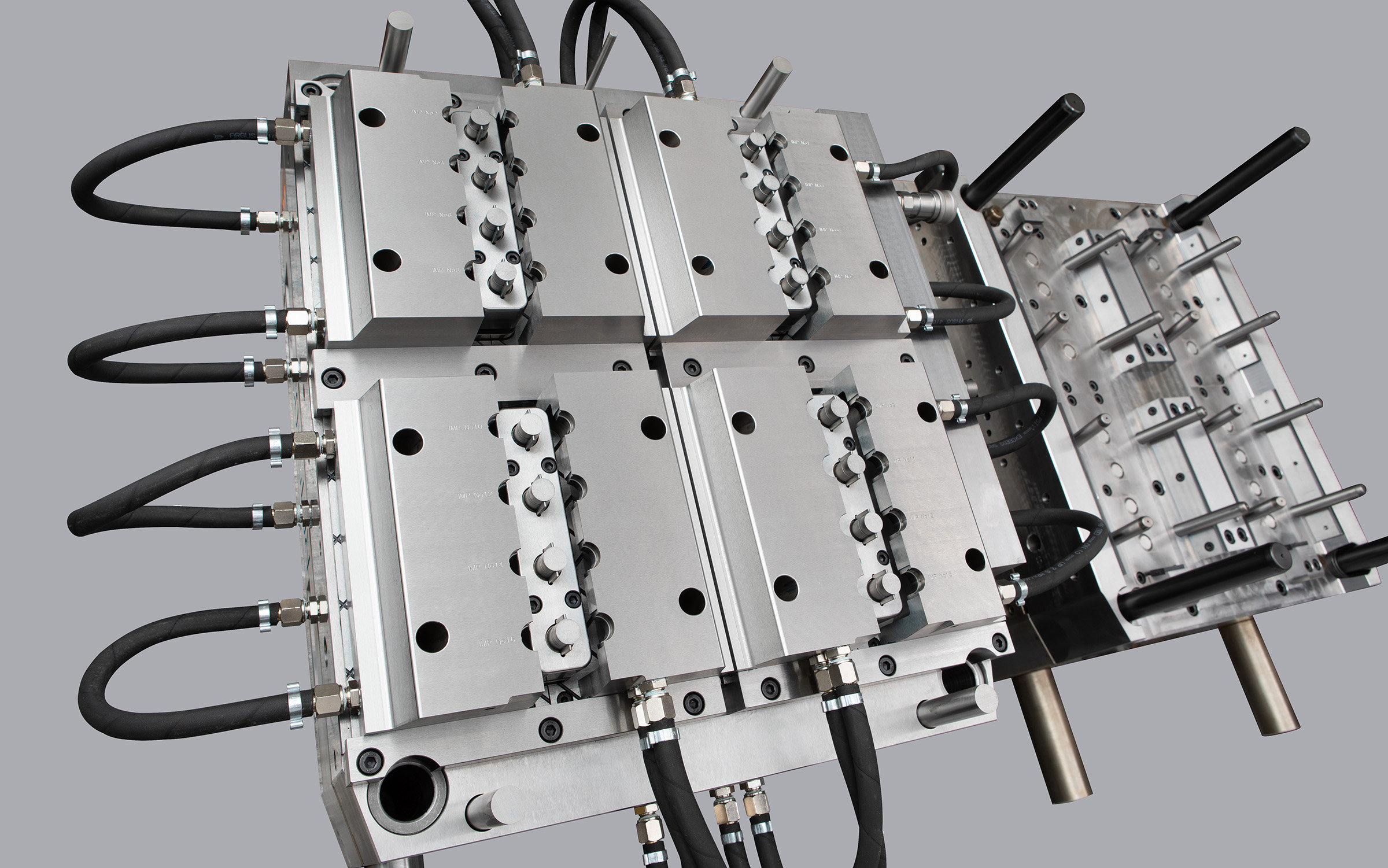

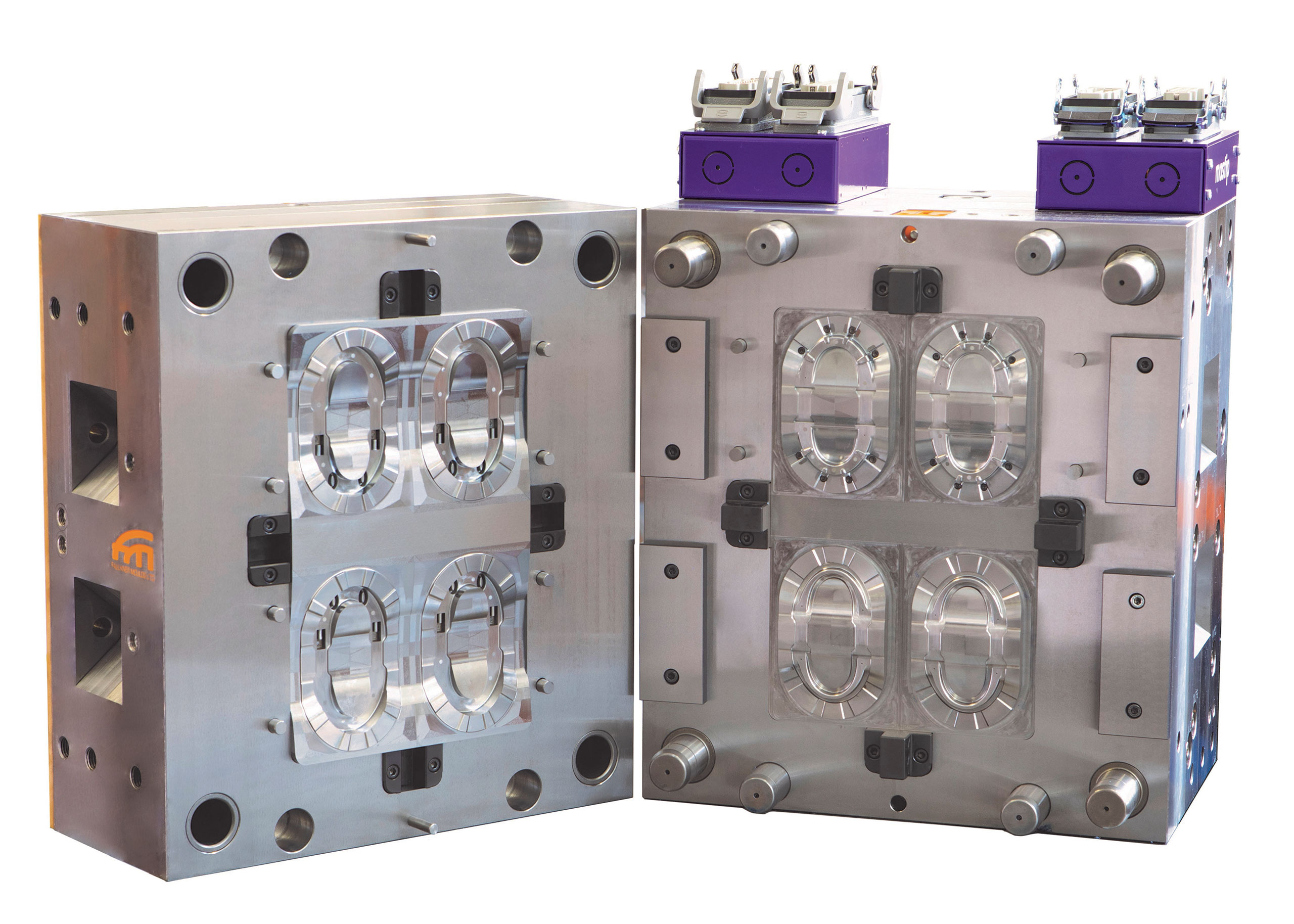

We have sound experience in high production, multi-cavity toolmaking with fast cycle times. We specialise in complex precision tooling solutions, including twin shot, overmould and unscrewing tools, serving many diverse markets such as the medical, electronics, packaging, consumer, industrial and automotive sectors.

Scroll down to view our GALLERY of examples and download our BROCHURE of customer TESTIMONIALS.

Award-winning twin shot oral medical devices, suite of multi-cavity convex ring tools, intravenous medical kidney device (box, buttons and internal mechanics), blood filtering inlets and outlets, ebola detection device, unscrewing capsule vessel, design and tooling for innovative NHS face visor headband, wheelchair emergency lifting equipment, hospital bed handles.

Multi-cavity high production tooling for household names, caps and closures, lids, price clips and tags, unscrewing mechanisms.

Fibre optic parts, optical lenses, mobile phone components, caravan control panel, intravenous medical device, twin shot automotive tracking electronic device.

Includes JLR, McLaren and Aston Martin. Rear piston, contact frame, contact path, dashboard, interior trim, fuel systems, award-winning large battery box, electrical control panel, electrical anti-theft device, award-winning awning light and lens.

Catering equipment for schools, hospitals, childcare centres and care homes; NHS face visor headband; Police vehicle light covers.

Award-winning Shocksafe shovel handle, Water and Rodent Non-Return Valve, building, wiring and plumbing products, wall-mountable gravity knife rack, commercial bakery products, knife handles, DIY products, dumbbells, snow shovel, pool table leg.